Fulton Offers the Best of Both Worlds for Performance and Cleaner Heat

HVAC is the typically largest single consumer of energy in a commercial building, and there is a lot of pressure today for green initiatives. There are essentially two paths to an HVAC solution that is better for the environment and costs less to run. You either need to use more efficient fuel or more efficient equipment.

The industry has steadily been working towards both of these ideas. Condensing boilers, first introduced in the 1990s have become increasingly more efficient. And over the years, our fuel sources have moved from coal to fuel oil to natural gas – a shift to simpler hydrocarbons which burn cleaner, releasing far less CO2 into the atmosphere. The next step in fuel efficiency is electricity, which means zero CO2 emissions.

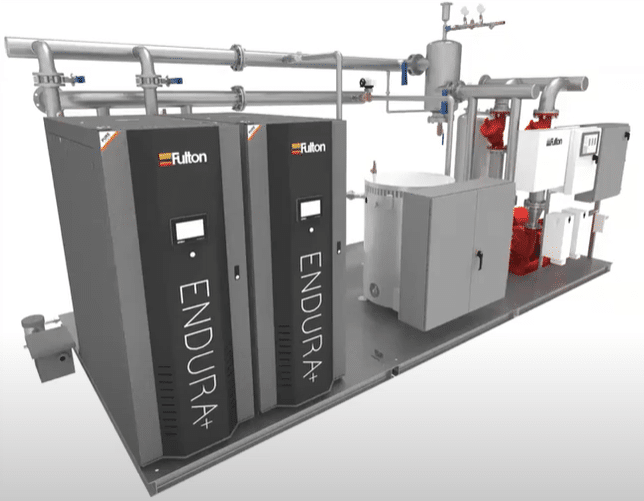

Fulton has developed a hybrid solution that combines condensing boilers powered by natural gas, with electric boilers. The condensing boiler carries the peak load capacity needs, while the electric boiler handles the shoulder loads or base load. Fulton offers an exclusive Sequence Control system that can be be programmed to automatically rotate and stage the equipment to optimize energy costs (gas fueled boiler) or emissions reduction (electric boiler), or a balance of both goals.

Electric Boilers

You’ve likely heard a lot about the many advantages of condensing boilers in recent years. Electric boilers also offer a number of benefits:

- Easier installation – no fuel gas vent, no combustion air, no fuel piping

- Near 100% efficiency – Heater elements are fully immersed, only jacket losses (outside shell insulation), operates at peak efficiency all the time

- Low maintenance – No refrigerant or compressor as with a heat pump system

- Excellent load matching – Instant turn-on (no combustion purging), turndowns of 100:1 possible

Control Systems Solutions

Fulton’s real advantage is the ability to integrate different types of equipment which normally cannot talk to each other – like an electric boiler and a high efficiency gas-fired boiler. Some example scenarios include:

- Rotate equipment to take advantage of off-peak rates using time-of-day

- Always designate the electric boiler as the lead to maximize CO2 reduction

- Rotate to gas-fired equipment based on outdoor air temperature

For more information, contact UEP with question or to estimate and engineer equipment for your next project. Here are a few resources available on Fulton’s website. For more technical data, please contact UEP.

Technical Series – One-page technical overview of features ideal for consulting engineers: Hybrid Electric Heating System – 80% Reduction of System Co2 Emission Without Installed Large Amperages

FB-E Brochure – Fulton Electric Steam Boilers (12kW to 180kW)

FB-LBrochure – Fulton Electric Steam Boilers (12kW to 1000kW)