When it comes to generator exhaust, the industry standard has long been field-fabricated, Schedule 40 carbon steel pipe, insulated to reduce surface temperatures. Recently, many designers and installers have come to recognize the benefits of factory-fabricated, UL listed systems, like what we specify and install for boilers and water heaters. Using UL listed systems ensures a consistent quality, cost effective system that are both lightweight and strong. So how do we ensure that we’re getting, safe, reliable generator exhaust systems?

As with all building systems, our priority is meeting the code. Codes can be tricky and the path to compliance is sometimes convoluted. You’ll need a little patience (and perhaps a map) to follow along but we’ll try to be as concise as possible.

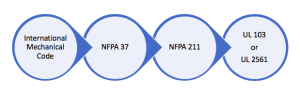

Section 915 of The International Mechanical Code (IMC) specifically refers to NFPA 37, Standard for the Installation and Use of Stationary Combustion Engines and Gas Turbines and stipulates that generator exhaust assemblies meet the requirements of UL 2200. NFPA establishes criteria for minimizing the hazards of fire related to the installation and operation of stationary combustion engines. Chapter 8.1 of NFPA 37 on the Design and Construction of Engine Exhaust Systems addresses the requirements for generator exhaust and provides guidelines for the exhaust system, stipulating the following:

• Systems shall withstand the anticipated exhaust gas temperatures.

• Systems shall withstand the intended service.

• Chimneys, where required, shall comply with NFPA 211.

• Systems shall withstand forces caused by the ignition of unburned fuel.

• Low points in the exhaust systems shall have drains.

NFPA 37 has referred us to NFPA 211, Standard for Chimneys, Fireplaces, Vents, and Solid Fuel-Burning Appliances. Chapter 6 is where we’ll find direction for Factory-Built Chimneys requiring that factory-built chimneys comply with UL 103 Standard for Factory-Built Chimneys for Residential Type and Building Heating Appliances, UL 2561 Standard for 1400oF Factory-Built Chimneys, or UL 959 Standard for Medium Heat Factory-Built Appliance Chimneys. Simply put, UL 103 is the listing for chimneys up to 1000oF and UL 2561 is the listing for chimneys up to 1400oF.

Did I mention that code compliance is convoluted? Here’s the map!

Now that we’ve established that factory-built systems meet the code, how do we specify them properly? Factory-built, UL listed products are offered as double wall (stainless inner/insulation/stainless outer) construction, creating a well-insulated, well protected system. Grades of stainless steel and insulation thickness can be determined by the engineer based on the specific application. Likely the biggest advantage to specifying a factory-built engine exhaust system is the warranty. A field fabricated system will carry a standard one-year warranty that covers the entire project. The Schebler P4 for system, commonly used for engine exhaust, comes with a five-year warranty standard and ten-year extended warranty so long as we size and design the system prior to release. That’s four additional years of guaranteed, reliable performance!

What are other advantages to factory-built engine exhaust systems? Design assistance. Generator exhaust systems need to be properly designed to ensure correct engine performance and safe operation. Utilizing a UL listed pre-engineered system allows much of the system design to be shouldered by the chimney manufacture, including vibration isolation, thermal expansion and explosion relief.

Here at UEP, we have experienced designers that assist with the layout, design and specification. We can create drawings, run calculations and ensure that you have the right accessories for the application. When faced with the challenge of a safe and reliable generator exhaust system turn to your trusted partner, United Energy Products. Contact our UEP engineers today to learn how factory-built generator exhaust can be implemented into your building project!