Here is a clear explanation on exactly how hydronic systems cost less, last longer and are better for the environment:

1. Lower initial costs

Hydronic chilled water systems have generally been thought to cost more to install. But that’s no longer true. Today’s advanced hydronic systems include application of technologies like integrated pipe systems that dramatically reduce piping, along with the use of variable speed pumps. These innovations bring the initial costs of a chilled water system in line with a VRF system.

2. Easier to install and maintain

VRV-VRF systems involve lots of refrigerant pipe and use oil for compressor lubrication. Control of oil return is critical. So special installation care is necessary to ensure that contaminants don’t enter the system and damage the compressor. Then there’s all the copper piping, refrigerant tubing and fabrication of brazed joints required. Proprietary VRF systems therefore require specialized technicians, and building owners are dependent on the manufacturer for the life of the system. Chilled water systems are easier to install and maintain. Their piping runs don’t require brazing or special soldering. Plumbers and pipe installers can handle the job, and there’s no oil or refrigerant to deal with.

3. Lower life cycle cost

The owner can expect significantly lower life cycle cost with a hydronic system. A VRF system lives a much harder life and consumes more energy, especially in the winter. The compressor is installed in a complex field installed refrigerant system and it is forced to reject its heat to air. Most important is that the compressor spins faster in heating, reducing the life of the bearings and compressor. Furthermore, it requires a very specialized mechanic. Compare this to a factory packaged water source heat pump unit. It is a much simpler system and has a proven track record of life expectancy well in excess of 20 years; twice that of DX systems. A water source heat pump system will consume much less energy, cost less to install, and live a much longer life.

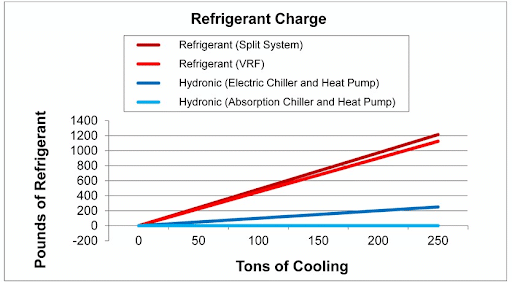

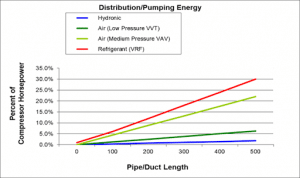

4. More Energy Efficient

Energy efficiency claims by VRF manufacturers have been difficult to verify, and without actual test data in hand it’s been difficult to determine the facts. The ASHRAE building comparative energy usage study shows that a VRF system is not as efficient as a geothermal system. In all cases, new variable speed hydronic chillers and heat pumps outperform variable speed VRF.

If you have more questions or are ready to discuss specs on a specific project, contact UEP to speak to our sales or engineering team.