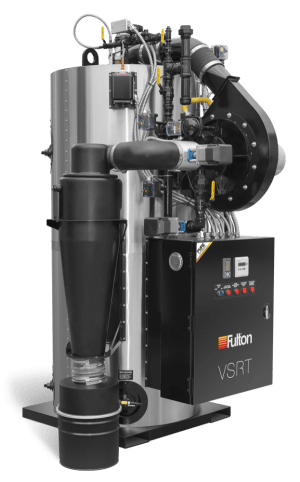

In 1949, Fulton engineered the first vertical tubeless steam boiler– a design feat that has yet to be surpassed in the HVAC industry. Today, the VSRT 250 (Vertical Spiral Rib Tubeless Steam Boiler) is the newest innovation brought to us by Fulton. The world’s first “refractory-free, fully-wetted tubeless vertical boiler”, the VSRT 250’s advanced design can support larger energy requirements and be utilized in an extensive variety of industrial building applications. The top benefits of this choice Fulton model include increased boiler efficiencies and lower operating costs.

Some defining highlights of the Fulton VSRT 250 include:

- Optimum Performance and Efficiency: With thermal efficiencies up to 86% without an economizer, this model leads the industry standard of steam boilers. A 10:1 turndown and O2 compensation deliver up to 15% additional efficiencies.

- Quality Steam: PURE Optimized technology guarantees up to a 99.75% verified steam quality, the cleanest and most reliable steam available.

- Minimal Footprint: Only a 14” flue necessary (as opposed to the 20” industry standard). With no external ASME piping required, the VSRT 250 is about half the footprint of other Firetube boilers.

- Durability: The four pass, tubeless vertical design minimizes corrosion and is built to withstand scaling issues. Fully wetted pressure and zero refractory aid in heat resistance and help reduce wear on equipment components. This means minimal maintenance and less water chemistry monitoring.

Curious if the Fulton VSRT 250 might be the solution to your building project? Or simply like to learn more? Contact UEP today to schedule a lunch and learn to discover this remarkable product!