With energy consumption at the forefront of our decision-making process in selecting equipment for commercial buildings, many people may wonder, when should I upgrade my fuel burning appliances? There are a few important factors to consider prior to making a change.

Efficiency

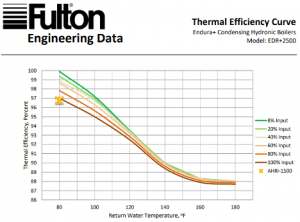

With efficiencies near 99%, condensing boilers and water heaters are the ideal choice when energy savings is your motivator. These appliances benefit from low return water temperatures, making them ideal for heating domestic hot water.

The challenge when upgrading to a condensing boiler for comfort heating is matching the supply water temperature to the existing terminal devices; reheat coils, fined-tube radiation, unit heaters, etc. Much of that equipment was selected on the old rule-of-thumb temperatures of 180oF heating water supply with a 20oF delta T. To get the full benefit of condensing, the return water temperatures need to be consistently below 130oF, as evident by the figure below, and the colder the better.

This is not to say that existing systems can’t benefit from the application of condensing equipment. They can. In the shoulder seasons, when the demand for heat is less, we can reset the supply water temperature based on outdoor air temperatures, using cooler supply water (and ultimately return water) to take advantage of the increased efficiencies when condensing.

Venting

Venting is the bigger deal when it comes to replacing a non-condensing appliance with a condensing one. Lower efficient boilers have traditionally been vented with NFPA 54, Category III flue for positive pressure, non-condensing applications or Category I flue for negative pressure, non-condensing applications. Category I flue, traditionally referred to as B-Vent, is single wall, natural draft and not designed to be air-tight. The costs associated with replacing the flue with Category IV materials and construction required for air-tight, positive pressure, condensing applications, could be significant. Additionally, tighter draft requirements of condensing appliances, may require the fan to maintain safe and efficient operation.

The Code

The design temperatures and venting requirements mentioned above ultimately are just cautionary advice to the building owner or engineering to select and install the equipment correctly. Most of the motivation to upgrade is driven by local code requirements for high efficiency equipment. There are exceptions to the code efficiency requirements for equipment installed in special building uses, like hospitals and labs, but most commercial buildings are obligated to use higher efficiency equipment when renovating a heating system.

At United Energy Products, we offer high-quality heating equipment for a variety of applications, both condensing and non-condensing. Contact us today to learn how we can assist you with upgrading your heating system!