Rather than having a large number of individual exhaust ducts for each appliance, or a fan that operates at full speed 24/7, ENERVEX’s Modulating Building Exhaust System (MBESx) senses when appliances are running and modulates with the load. It assures proper exhaust rates at any time no matter the demand and can reduce the exhaust rate of conditioned air by up to 60-70%. This demand-controlled ventilation system is designed for multi-story buildings with multiple kitchen hoods, bathrooms or clothes dryers on multiple floors.

How it Works

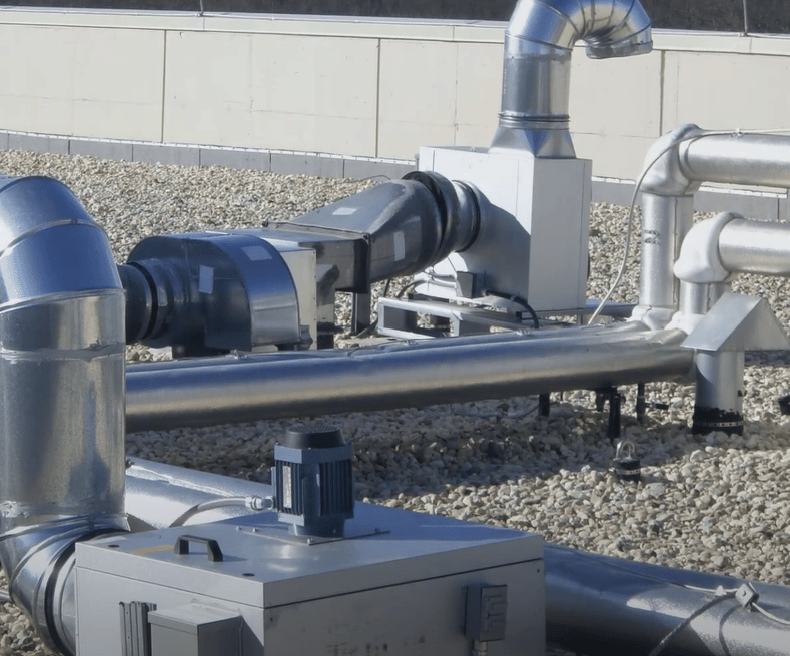

The MBESx system consists of a BEFx Exhaust Fan and an MEC 24 Constant Pressure Controller with an XTP Pressure Transducer. The system uses an EC-motor and an MSC EDrive E3 Motor Speed Controller.

The MEC 24 control modulates the speed of the BEFx ventilator based on the ventilation demands of the building to maintain the set-point during normal operation. The MBESx ensures the set-point is reached within 30 seconds of system start-up and is maintained with a tolerance of 0.01” W.C.

When a number of clothes dryer, kitchen or bathroom exhausts are connected into a common duct, the MBESx will modulate with the load. Once an appliance starts up, the pressure will change in the common duct and the MBESx will react by increasing speed and vice versa.

During normal operation, ramp-up and ramp-down time of the fan will be no more than 20 seconds. In the case of a mechanical or electrical failure, the control goes into alarm and sets the ventilator to run at 100% speed. If connected, the alarm signal will be sent to the Building Management System.

Features

- Automatically controls fan speed based on current demand

- Costs less to operate than a fixed-speed CAV system

- Extremely suitable for retrofitting

- Discharges inline or on the roof, making it easier to clean architectural vents

- Quiet performance eliminates constant fan noise & noise from speed variations

- Ability to combine ducts & reduce duct sizes cuts material & labor costs

- Variable speed, direct-drive fans eliminate broken belts

Benefits

- Costs 55% less to operate than a fixed-speed CAV system

- Saves up to 85% of the cost of exhausted conditioned air

- Unused air can save $500 per kitchen hood & $200 per bathroom annually

Contact UEP to discuss how to see if this system is a fit for your next project.

Here’s a great video from Enervex that further explains the MBESx system.