Whether it’s because we’re smarter than previous generations of engineers or the codes have forced us in this direction, engineers are consistently doing more with less. Gone are the days of rules of thumb and safety factors. If orange is the new black, green is the new gold.

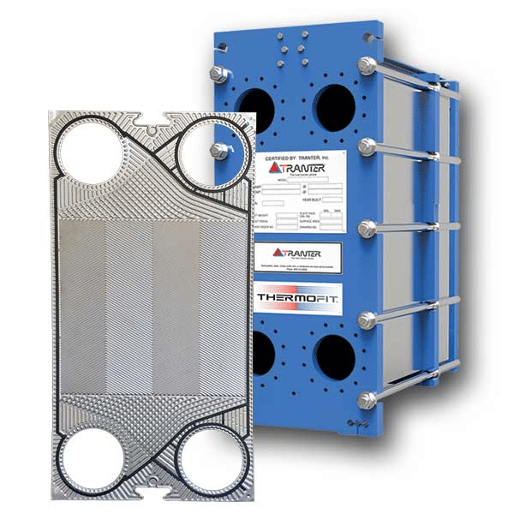

One of the many ways engineers are saving energy and money for their clients is by incorporating heat exchangers in the HVAC design, either to recover waste heat or to avoid mechanical cooling when outside temperatures are suitable. Gasketed plate and frame heat exchangers are an ideal solution for both processes. The trick is to ensure a good selection. Sometimes less is more when considering fouling, excess surface area and plate expansion.

Fouling Factor

HVAC systems will become “dirty” with age and the way we compensate for that dirtiness is to select equipment with a fouling factor, an increased resistance to heat transfer. When selecting a gasketed plate heat exchanger (GPHE) for an HVAC application, one’s instinct might be to use fouling factors similar to those for shell and tube heat exchangers. Resist the temptation! For various reasons that are primarily linked to the design of the plates, GHPE’s don’t foul in the way that shell and tubes do. Using a fouling factor that is too high will ultimately result in an oversized heat exchanger. An oversized heat exchanger will result in low flow rates within the heat exchanger which leads to increased fouling. Sound like a vicious cycle? That’s because it is! The moral of the story is to keep fouling factors low and velocities high.

Excess Surface Area

Heat exchanger selection software will often allow the engineer to specify excess surface area. Excess surface area is another way of saying fouling factor. If you’re more comfortable with excess surface area, by all means specify your GPHE that way, but don’t double down by also adding a fouling factor. Using both will get you caught in that vicious cycle we mentioned above, but it’ll get you there faster! The moral of the story here is one or the other, but never both.

Plate Expansion

The beauty of the GPHE is that you can add heat transfer capacity to the equipment by adding extra plates if the frame is large enough to accommodate them. For this reason, engineers will often specify plate expansion for future growth. This is a great idea if you know that there is impending growth at the project site. Plate expansion is not a great way to get extra capacity out of a system that is already suffering from some of the common ills, like low delta T. In that case, doubling the plates often nets a very small return on your investment. Unless you know that there is a plan for future growth, plate expansion will mostly likely result in a larger frame and more expensive heat exchanger.

United Energy Products proudly represents Tranter, a worldwide manufacturer of commercial heat exchangers. Reach out to us at info@uepsales.com for assistance with your GPHE selection.